Local company invests heavily in asphalt manufacture

Article by Anesta Henry Published on

August 18, 2021 first appeared in Barbados Today.

Eighty per cent of the asphalt being used to repave the island’s road network in the ongoing road rehabilitation programme is coming from a locally-owned company which is the sole producer of bitumen asphalt in the region.

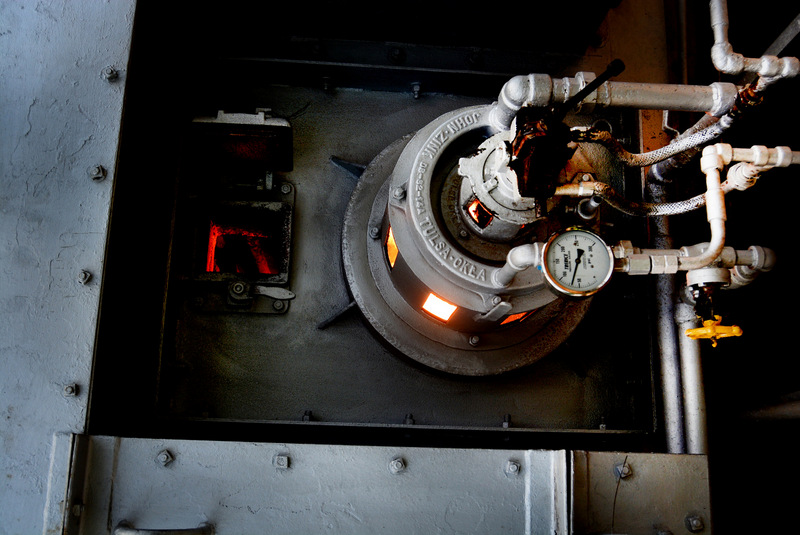

Minister of Transport, Works and Water Resources Ian Gooding-Edghill who toured the facilities of Asphalt Processors Inc. (API) at Lower Greys, Christ Church on Tuesday, commended the company for recently investing over $5 million in the manufacturing plant and close to $600 000 in new laboratory technology during the COVID-19 pandemic.

Gooding-Edghill said Barbados has been using the same asphalting on the road network for approximately 60 to 70 years. He said given the recent upgrades at API’s operations, the company is now positioned as a global industry leader, primed to be able to collaborate with the Governments of Barbados to provide the key ingredient Polymer Modified Asphalt (PMA) to develop, enhance and evolve essential infrastructure to meet current international asphalting standards.

He said: “What is also very impressive is the fact that they would have worked on repaving the runways at the Grantley Adams International Airport and they would have been responsible for taking the lab samples.

“And the cooperation that they had with a United States-based company that also ensured that the lab work which was done right here at this plant was internationally-recognized and certified.

“Certainly, after the tour of the lab, I must also compliment the team here at API for the wonderful investment undertaken. So, you have a Barbadian-owned and operated company operating at the various highest levels of international standards. It is the only company in the region that is so certified to execute polymer modified asphalt,” Gooding-Edghill added.

The Minister also announced that as Government continues to focus on its road improvement programme, it will be ensuring that contractors continue to purchase asphalt from API which would lead to increased sales for the company.

Managing Director of API, Errol Lynch, said as the sole producer of asphalt in Barbados, the recent improvements have enabled the 20-year-old company to now be recognized as the only asphalt plant in the region with the capacity to manufacture, supply, and test a specific type of Polymer Modified Asphalt that complies with stringent international standards.

He explained that PMA grade, used on the runways at GAIA, is the most cost-effective and environmentally safe approach to road paving and preventative maintenance and construction of all major highways.

“It was the first time that the runway of Barbados was repaved solely with materials coming from Barbados. And I think that it is the first in the Caribbean to have this type of product on the runway,” Lynch said.

“So we are actively looking at any airport that has to be repaved in the region to be able to reach out to the contractors because we would have to be sub-contracted because we don’t build roads.”

The managing director said the notable improvements at API, a longstanding member of the International Asphalt Institute, ensure the company’s products continue to meet the industry standards for asphalt materials as defined by the American Society for Testing and Materials (ASTM) and the American Association of State Highway and Transportation Officials (AASHTO).

Lynch further explained that while road infrastructure work throughout the Caribbean is currently down, the export market to mainly Trinidad and Guyana takes up about 70 per cent of the company’s production.

He said API’s main competition comes from outside the Caribbean, through international companies.

Lynch said: “Every day we are actually developing our export market within the region. The market is ripe to be able to export to these other territories. We do quite a bit of work in St Lucia as well and St Vincent. We worked with the St Kitts government a couple years back and we are trying to develop that in the next two years.”

(AH)